When a water pipe breaks or natural disaster happens there are considerable damage to buildings. For floor coverings, e.g. as wood, carpet, stone, PVC Water damage is an extreme stress, since these coverings are typically designed for use in dry conditions.

LÄGLER® was effected by such damage due to a heavy storm last August.

Read on to see what happened to us...

Wood has many positive features and is an excellent material for floors. It is pleasant to walk on and provides an excellent indoor climate. But where there are benefits, there are drawbacks. A disadvantage is that wood is susceptible to high humidity levels. The tubular structure of the wood cells and the tendency to absorb moisture from the environment, the water can quickly and in larger quantities get into the core of the wood. It soaks the water in like a sponge and swells. Cupping is the result. Since each type of wood has a different cell structure and differing swelling behavior, the damage can be minor or extreme. Therefore, it is important to remove the water as quickly as possible from the wood.

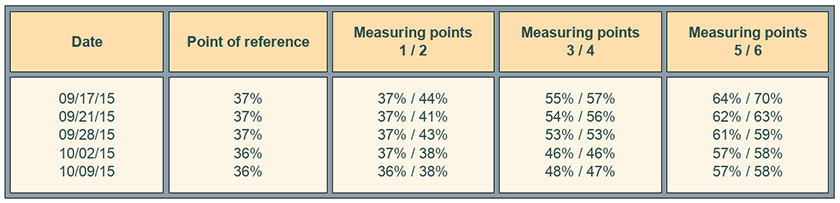

After pumping out the water we determined with a moisture meter, how much water has been soaked into the wooden floor and the walls of the classroom. The first measurements shortly after removal of the water already showed the extent of the damage. On the outside wall to the courtyard particularly high moisture levels were measured. On the upper part of the outer wall 37% of moisture were measured...

The lower we measured (measuring points 1 ... 6), the higher the values. At measuring point 6 close to the floor, before drying, even 70% moisture were measured.

To initiate the drying process, the wood floor was sanded roughly on the advice of the expert before drying with a dehumidifier. By removing the finish layer with a 36 grit on the HUMMEL® the moisture could be removed faster from the wood and the cupping was almost completely eliminated (Pic. 7).

The second sanding cut with the HUMMEL® at a grit 60 followed. Both cuts were performed at an angle of 15° to the direction of the laying pattern / grain.

It is crucial that the drying process of the wood floor is done uniformly and not too fast. The expert in dehumidification provided us with a commercial dehumidifier that is designed for the volume of about 300 m3 / 10600 ft3 (Pic. 8).

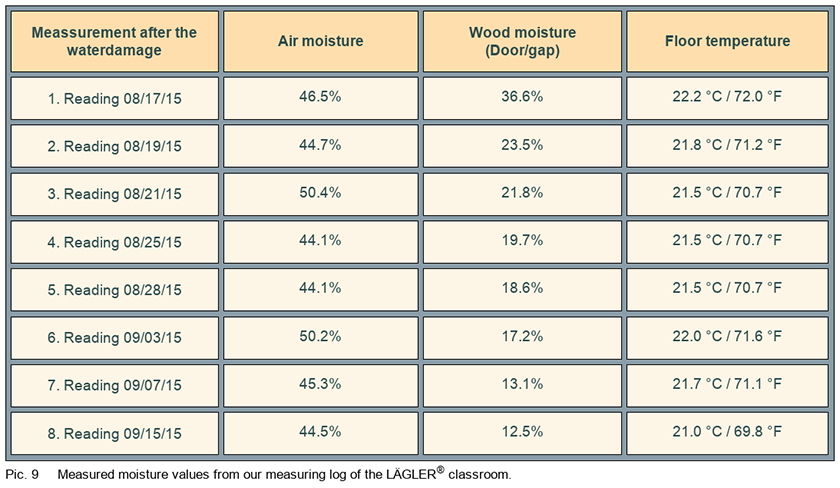

A week after the rough cut we started drying using the dehumidifier. The unit was placed in the conference room and operated over a period of 2 weeks. During the drying process to check the progress, the moisture content was measured at different points in the room and on the wood floor.

While the humidity and the soil temperature remained relatively constant, the moisture content steadily declined for a total of about 5 weeks drying time, an acceptable value of 12.5% moisture content was reached. The result table in Pic. 9 shows the moisture content during the drying process.

The first step we applied a 2 component oil that was buffed in with a beige pad and the SINGLE (Pic. 11). After the recommended drying time of the oil the first finish layer was rolled on.

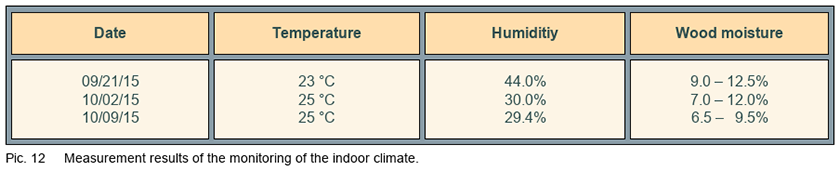

A few days before, during and after the work LÄGLER® staff checked the indoor climate (Pic. 12). The measured values were safe, so that the work could be continued and completed by the curing of the UV finish. A UV coating has the advantage that the surface can be operated faster. The UV finish, however, has to be cured with a special UV machine.

After the drying of the first finish layer a second finish layer was applied without intermediate sanding and also allowed to dry.

Then the final coat (Pic. 13) was cured by strong ultraviolet radiation with a specially adapted mobile UV light. This hardens the finish instantly and forms a resistant protective layer.

For lack of experience in dealing with UV finish an expert should be consulted in any case, otherwise this may lead to poor results. In addition, training is required for working with the mobile UV light, otherwise the safety of the operator (eyes) is threatened by the strong radiation.

When the moisture levels decrease to normal levels, the wood floor can be sanded as usual. In our case, to speed up the process UV finish was a great choice. The the first coat of oil before the UV finish ensures a smooth, matte, natural-looking surface (Pic. 14). The protective effect of the UV finish is stronger than conventional finishes. By the way a few weeks ago the same floor got hit again with water...

The exhibition "HOLZ-HANDWERK" in Nürnberg attracted along with with the "Fensterbau Frontale" around 110,000 visitors, including many from abroad. From March 16 to 19 1,296 exhibitors from 40 countries presented their products to the public and made the "HOLZ-HANDWERK 2016" to an impressive industry highlight, which also LÄGLER® could not miss.

The internationally significant exhibition "NWFA Wood Flooring Expo " with topics related to wood floors took place from 27 - April 30, 2016 and was held in Charlotte / North Carolina, USA.

LÄGLER® focus this year was the merge with long time partner Palo Duro Hardwoods Denver / USA and the introduction of the PST® to the North American market.